Overcoming outdated HMI hardware, software limits

When human-machine interface hardware and software are outdated, pain points can be many, including lack of training for less-experienced operators, connectivity and remote access to machine condition or performance information. Get help below and in July 13 webcast.

Learning Objectives

- Use upgraded human-machine interfaces (HMIs) to help overcome effects of operator turnover.

- Deploy real-time training at the machine with modern HMIs.

- Augment connectivity and remote access to machines with updated HMI hardware and software.

Modern human-machine interface (HMI) hardware and software can help resolve machine and operations control challenges, according to the July 13 webcast, “How to overcome limits of outdated HMI hardware and software.”

On the topic of industrial HMIs, Brian Young, Northeast and Canada regional sales manager for Exor, asks the webcast audience for the biggest pain point:

- Operator turnover and training

- Connectivity and remote access

- Accessing and integrating data

- Antiquated feature set

- Other challenges.

Poll results from those participating live are to be included in the archived version of the webcast. A question-and-answer session after the presentation addresses audience questions for those listening live and is included in the archived version.

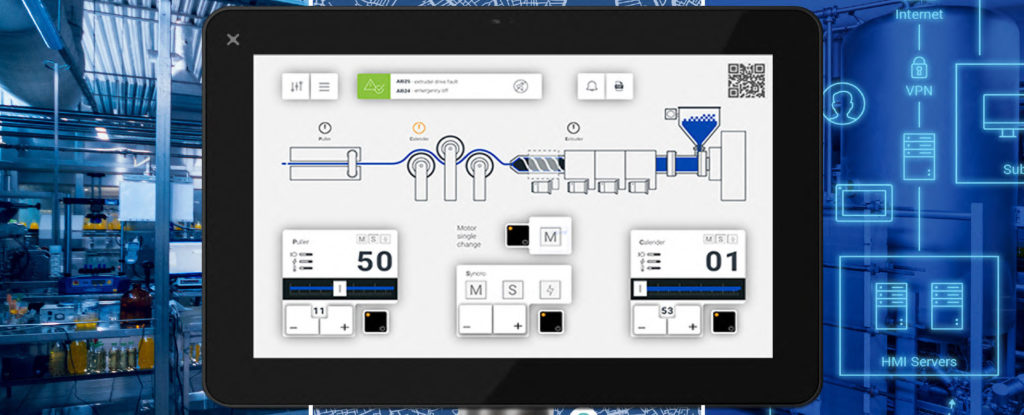

Modern human-machine interface hardware and software help resolve many manufacturing challenges related to training, connectivity, integration, and troubleshooting, explained Brian Young, Northeast and Canada Regional Sales Manager for Exor, in a July 13 webcast, “How to overcome limits of outdated HMI hardware and software.” Exor JMobile Software for Industrial Edge Management, for instance, covers the connectivity from edge to cloud and improves device management, process management

and data visualization. Courtesy: Exor

HMI upgrade advantages

Young said enhanced HMI displays:

- Provide machine or line operators with advanced problem-solving resources, improve efficiency and productivity.

- Increase remote connectivity to resolve problems quickly and efficiently, provide data in a more visual format than many prior designs and provides a secure method for machine or operations troubleshooting and maintenance.

- Deliver better data access, and integration makes better use of data more quickly.

- Help bridge operations technology (OT) and information technology (IT) architectures with modern platforms.

Updated software benefits include ability to share data seamlessly within the network of edge points, a more intuitive user experience and ease of implementation, Young said. Integrated web technology provides advanced control and remote supervision from any browser and device.

Edited by Mark T. Hoske, content manager, Control Engineering, CFE Media and Technology, mhoske@cfemedia.com with information from the July 13 webcast, archived for 1 year.

KEYWORDS: Human-machine interface, HMI modernization

CONSIDER THIS

How many challenges could modern HMI hardware and software resolve in your manufacturing applications?

ONLINE

https://www.controleng.com/webcasts/how-to-overcome-limits-of-outdated-hmi-hardware-and-software/

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.