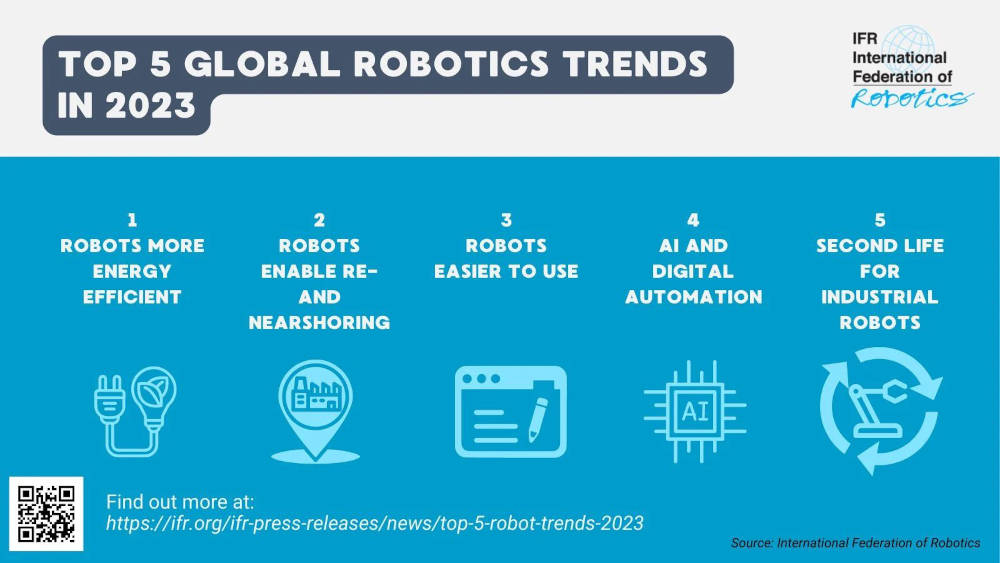

Five robot trends for 2023

The International Federation of Robotics (IFR) analyzes the top five trends shaping robotics and automation in 2023.

Robot insights

- The International Federation of Robotics highlights several trends on the robotics industry and where the future lies. Energy efficiency, reshoring and improved ease of use are among the biggest.

- Another interesting trend is using new tech equipment to give a robot a “second life” with manufacturers have repair centers to let the robots continue to provide value to their customers.

Robots continue to grow in manufacturing and non-manufacturing operations. The International Federation of Robotics (IFR) highlights five trends for the robot industry for 2023.

1. Improved energy efficiency.

Energy efficiency is key to improve competitiveness amid rising energy costs. The adoption of robotics helps to lower energy consumption in manufacturing. Compared to traditional assembly lines, considerable energy savings can be achieved through reduced heating. At the same time, robots work at high speed, increasing production rates so that manufacturing becomes more time- and energy-efficient.

Today’s robots are designed to consume less energy, which leads to lower operating costs. To meet sustainability targets for their production, companies use industrial robots equipped with energy saving technology: robot controls are able to convert kinetic energy into electricity, for example, and feed it back into the power grid. This technology reduces the energy required to run a robot. Another feature is the smart power saving mode that controls the robot´s energy supply on-demand throughout the workday. Since industrial facilities need to monitor their energy consumption even today, such connected power sensors are likely to become an industry standard for robotic solutions.

2. Reshoring.

Resilience has become an important driver for reshoring in various industries: For example, car manufacturers are investing heavily in short supply lines to bring processes closer to their customers. These manufacturers use robot automation to manufacture powerful batteries cost-effectively and in large quantities to support their electric vehicle projects. These investments make the shipment of heavy batteries redundant. This is important as more and more logistics companies refuse to ship batteries for safety reasons.

Relocating microchip production back to the US and Europe is another reshoring trend. Since most industrial products now require a semiconductor chip to function, their supply close to the customer is crucial. Robots play a vital role in chip manufacturing, as they live up to the extreme requirements of precision.

Courtesy: International Federation of Robotics (IFR)

3. Ease of use.

Robot programming has become easier and more accessible to non-experts. Providers of software-driven automation platforms support companies, letting users manage industrial robots with no prior programming experience. Original equipment manufacturers work hand-in-hand with low code or even no-code technology partners that allow users of all skill levels to program a robot.

The easy-to-use software paired with an intuitive user experience replaces extensive robotics programming and opens up new robotics automation opportunities: Software start-ups are entering this market with specialised solutions for the needs of small and medium-sized companies.

For example, a traditional heavy-weight industrial robot can be equipped with sensors and software that allows collaborative setup operation. This makes it easy for workers to adjust heavy machinery to different tasks. Easy-to-use programming interfaces, that allow customers to set up the robots themselves, also drive the emerging new segment of low-cost robotics.

4. Artificial intelligence (AI) and digital automation.

Propelled by advances in digital technologies, robot suppliers and system integrators offer new applications and improve existing ones regarding speed and quality. Connected robots are transforming manufacturing. Robots will increasingly operate as part of a connected digital ecosystem: Cloud Computing, Big Data Analytics or 5G mobile networks provide the technological base for optimized performance. The 5G standard will enable fully digitalized production, making cables on the shopfloor obsolete.

Artificial intelligence (AI) holds great potential for robotics, enabling a range of benefits in manufacturing. The main aim of using AI in robotics is to better manage variability and unpredictability in the external environment, either in real-time, or off-line. This makes AI supporting machine learning play an increasing role in software offerings where running systems benefit, for example with optimized processes, predictive maintenance or vision-based gripping.

5. Industrial robots getting a second life.

Since an industrial robot has a service lifetime of up to thirty years, new tech equipment is a great opportunity to give old robots a “second life.” Industrial robot manufacturers like ABB, Fanuc, KUKA or Yaskawa run specialized repair centers close to their customers to refurbish or upgrade used units in a resource-efficient way. This prepare-to-repair strategy for robot manufacturers and their customers also saves costs and resources. To offer long-term repair to customers is an important contribution to the circular economy.

– Edited from an IFR press release by CFE Media and Technology.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.