Propulsion lab offers testing conditions for hypersonics, combustion

Purdue's High-Speed Propulsion Laboratory will feature testing capabilities for innovative research in rocket combustion and gas turbine engines.

Purdue University’s work in national security took another giant leap forward with university trustees’ approval of a state-of-the-art high-speed propulsion laboratory, putting the university’s hypersonic testing capabilities on scale with large industry partners.

Hypersonic defense abilities are considered “game-changing” technologies. With systems that can travel at speeds of Mach 5 or faster and are highly maneuverable, hypersonics are potentially very effective against heavily defended areas.

The High-Speed Propulsion Laboratory will be located in the Discovery Park District at Purdue. The new lab will provide testing capabilities at the extreme pressure and temperature conditions experienced in actual hypersonic flight, significantly enhancing Purdue’s research and development capabilities.

The lab will feature new testing capabilities for innovative research in rocket combustion and gas turbine engines, continuing Purdue’s history of research and development in those areas.

Once the $73 million lab is complete, Purdue will be the only university in the nation with such a high level of propulsion capabilities, providing the capacity to perform propulsion testing reaching a scale only found in government or large defense contractor facilities. The High-Speed Propulsion Laboratory, unlike similarly equipped government or industry facilities, will be available to a very broad set of researchers interested in working with Purdue to test their equipment.

“Purdue’s plans for the High-Speed Propulsion Laboratory are a testament to our continued focus on national security,” said Theresa Mayer, executive vice president for research and partnerships. “Purdue researchers have deep expertise in this area of critical importance to our nation. By harnessing Purdue’s expertise, capabilities and capacity for advancing hypersonics R&D, we can help to give the U.S. a competitive advantage against our near peer adversaries.”

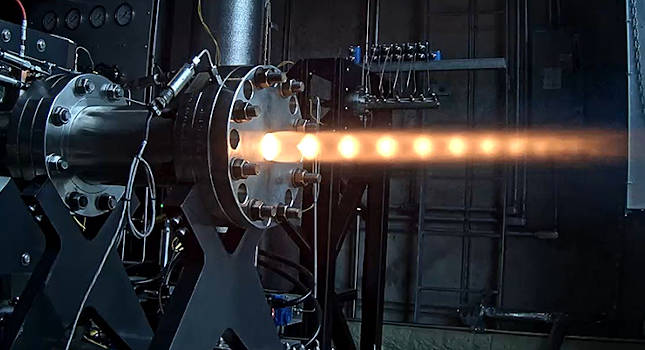

A solid fuel ramjet combustor is among the many multidisciplinary facets of propulsion innovation and research at Purdue’s Maurice J. Zucrow Laboratories. Courtesy: Carson Slabaugh, Purdue University

The High-Speed Propulsion Lab will work in concert with Purdue’s rapidly advancing expansion in hypersonics. The lab proposal to the trustees included a high-pressure air plant, which will upgrade existing equipment and support all of Purdue’s hypersonic and propulsion testing capabilities. Substantial completion of the lab is expected in November 2024.

Purdue’s investments in hypersonics position the university as a compelling partner for national defense projects from industry and government. Hypersonics is a critical area of focus under Purdue’s Next Moves strategic initiatives that will advance the university’s competitive advantage.

The new lab facilities will enable testing for the Hypersonics Advanced Manufacturing Technology Center (HAMTC), which was announced in February.

It will also complement testing that will take place within the Hypersonics and Applied Research Facility (HARF), which broke ground in late 2021 in the Discovery Park District at Purdue. HARF will house the only Mach 8 quiet wind tunnel in the world and the hypersonic pulse (HYPULSE) reflected shock/expansion tunnel. The Mach 8 tunnel simulates velocity but does not simulate the extreme heat conditions, while the HYPULSE simulates the extreme conditions of temperature and pressure for a few milliseconds.

The lab includes the substantial infrastructure required to create the conditions of hypersonic flight to meet the needs of researchers from industry, other universities and federal laboratories and agencies.

“With the Purdue faculty and significant input from industry and government partners, we designed the High-Speed Propulsion Lab to fill a testing capability gap that exists between fundamental research and test and evaluation at full-scale,” said Scott Meyer, managing director of Maurice J. Zucrow Laboratories. “We are essentially expanding the scale and capacity of research and development experiments to actual flight systems.”

Carson Slabaugh, associate professor of aeronautics and astronautics, said Zucrow’s extensive research with major defense contractors, small businesses and national laboratories is working to bridge the wide technological gap from laboratory to engine.

“High-speed vehicle design is an exceptionally multidisciplinary field, and component interactions must be addressed through an integrated approach that supports rapid prototype evaluation and iteration,” he said. “The High-Speed Propulsion Laboratory will enable vertically integrated research, development, testing and evaluation focused on high-speed propulsion systems, which will be a leap-ahead capability for U.S. interests in hypersonic flight.”

This work continues Purdue’s success of creating a hub of hypersonics research and testing facilities to help the U.S. meet and exceed the progress of adversary nations. Success on this front enhances a crucial national asset to the nation.

In addition to increasing testing capabilities, the new high-speed laboratory will provide opportunities to engage the talents of more graduate students. As many as 80 additional graduate students will be needed to perform the work this new lab affords.

“The High-Speed Propulsion Laboratory gives us greatly enhanced capabilities for testing and research on hypersonic vehicle propulsion concepts, including supersonic combustion ramjets (scramjets), and other advanced concepts for both air-breathing and rocket propulsion,” said Robert Lucht, director of Zucrow Laboratories. “This new facility will also provide our industry and government partners with the opportunity to assist in the education and training of a critical U.S. hypersonics workforce.”

– Edited by Chris Vavra, web content manager, Control Engineering, CFE Media and Technology, cvavra@cfemedia.com.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.